Environmentally Sound Technology Information Portal

Preventive solutions

Some of these methods are known to be employed in maritime industries for underwater infrastructure maintenance.

1. Antifouling Coatings

Biocidal Coatings: These coatings release substances toxic to fouling organisms, preventing their attachment and growth.

Non-Biocidal Coatings: These coatings use physical or chemical means to make surfaces less attractive to fouling organisms.

2. Ultrasonic Antifouling:

Ultrasonic systems emit high-frequency soundwaves that deter the settlement and growth of fouling organisms on surfaces.

3. Ultraviolet (UV) Light:

UV light can be used to disrupt the DNA of microorganisms, preventing their growth and reproduction.

4. Surface Texture Modification:

Altering the surface texture of materials to make them less conducive to the attachment of fouling organisms.

5. Barnacle-Resistant Materials:

Developing materials that naturally resist barnacle attachment, reducing the need for antifouling treatments.

6. Electrochemical Methods:

Applying electric currents to surfaces to deter biofouling by disrupting the attachment and growth of organisms.

Reactive solutions

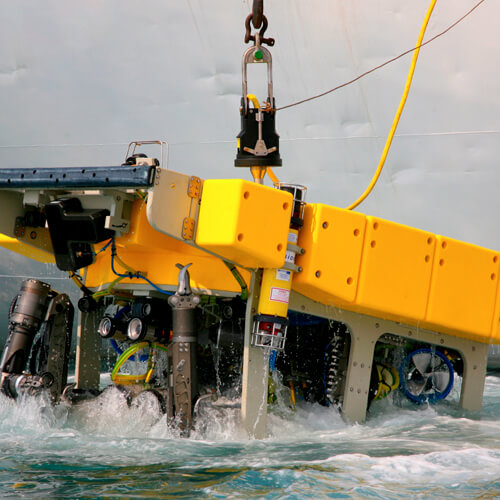

Various solutions are available for reactive management of biofouling. Advances in robotics and automation continue to influence the development of more efficient and precise monitoring and cleaning technologies, but the main choice continues to be between ROV (Remotely Operated Vehicles or underwater robots) and diver-operated methods. It is common to use a combination of these technologies for comprehensive biofouling management. The final option is based on factors such as the nature of the structure, the extent of biofouling, environmental safety of the planned operation, accessibility to the site, availability of services and cost.

7. Remotely Operated Vehicles (ROVs):

Inspection: Underwater robots or ROVs equipped with cameras can be used to inspect and make a preliminary assessment of biofouling.

Cleaning: aside from inspection, many ROVs are focused on cleaning of submerged surfaces. They are often employed in offshore oil and gas installations, ship hulls, and other underwater structures. In-water cleaning options are highly varied based on the method of cleaning and the capability (or not) for the technology to capture biofouling waste. The method of cleaning can be based on different types of brushes, scraping sections or high-pressure water.

8. Diver-Based Methods:

Inspections and Surveys: Divers can conduct visual inspections and surveys to assess the extent of biofouling and determine the appropriate cleaning method.

Manual Cleaning: Divers can manually clean submerged surfaces using brushes, scrapers, or other tools.

High-Pressure Water Jets: Divers may use high-pressure water jets (or carts) to dislodge and remove biofouling from surfaces. Some are specifically used for propeller polishing.

9. Biofouling Monitoring Systems:

Monitoring: Aside from noon reporting, there are advanced monitoring systems that use sensors quantify fuel consumption and detect an increase in the hull resistance of a ship – commonly due to biofouling, and allowing for an early detection and further action.